Applying protective film to sheet metal is nothing new – it is part of everyday life at many sheet metal and stainless steel sheet production companies. The application process is continuous.

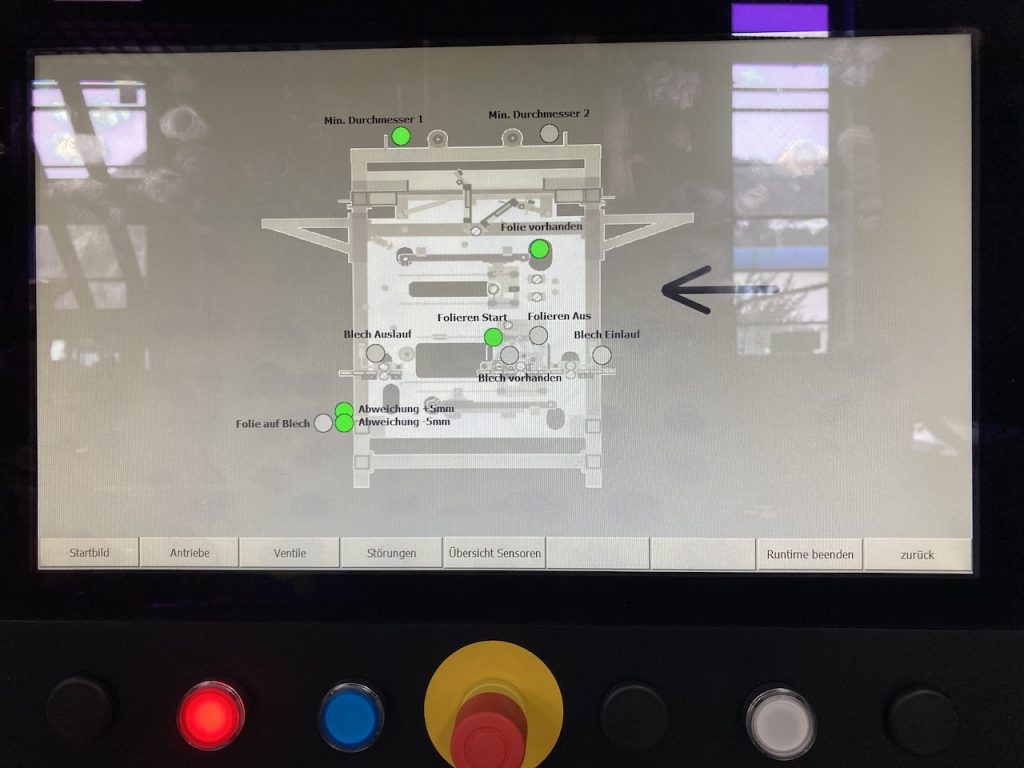

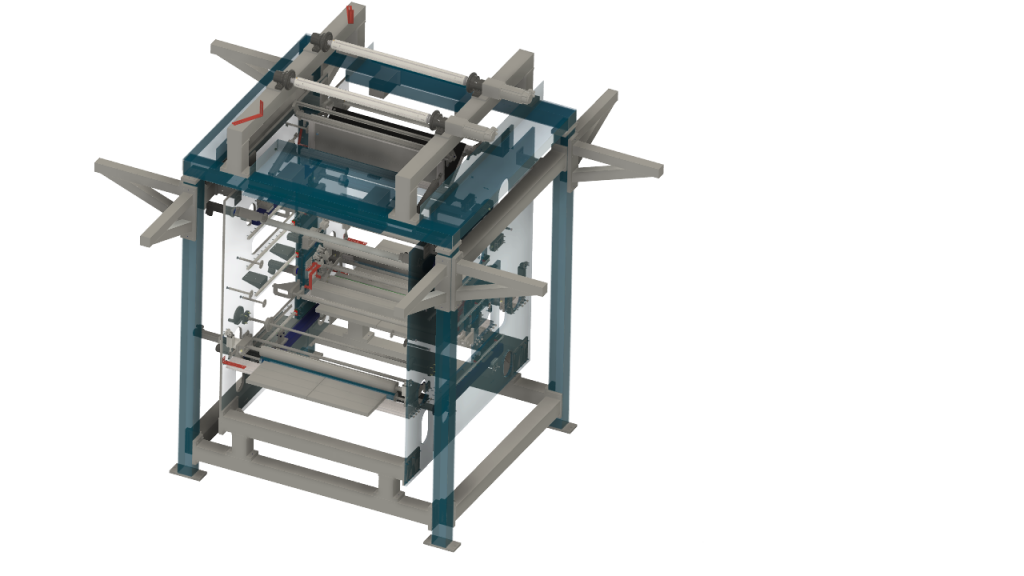

In our case, the protective film should be applied using the “stop and go principle” – i.e. not continuously but over specified lengths, interrupting the application for a length “X” and then reapplying it. And all this without creases or bubbles! There were no role models: Refoil had to solve the task by trial and error. Refoil solved these challenges. As the system had to fulfill this task in the future in a line for the production of high-quality trapezoidal sheets, the greatest care and reliability was required.

Technical details:

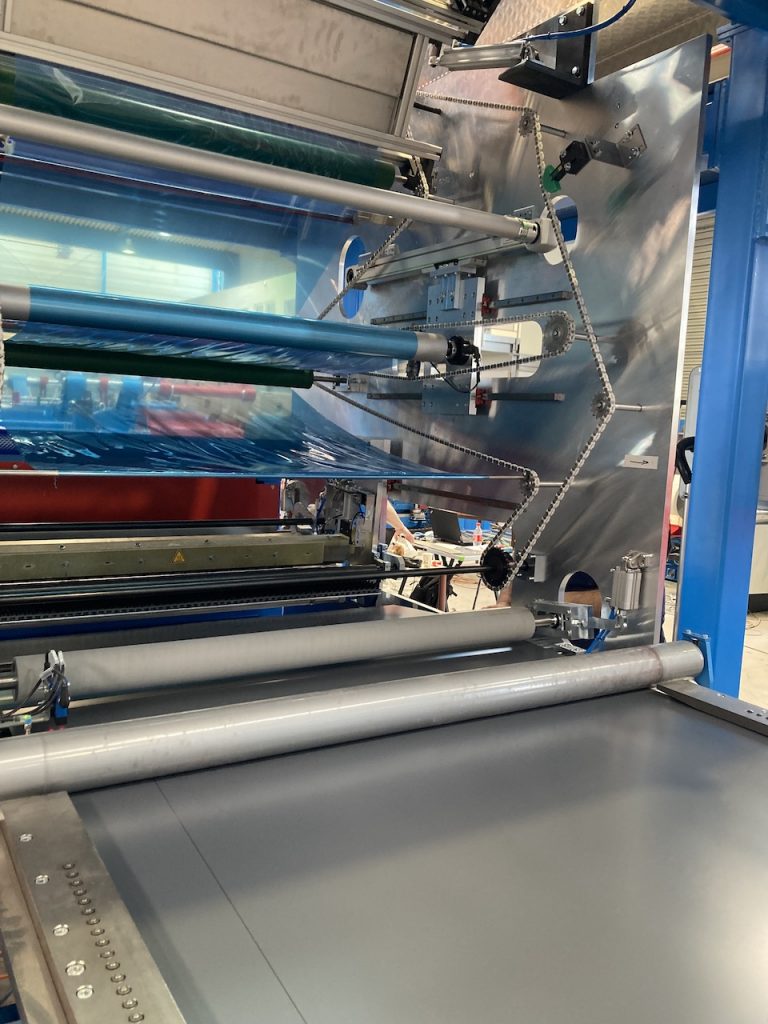

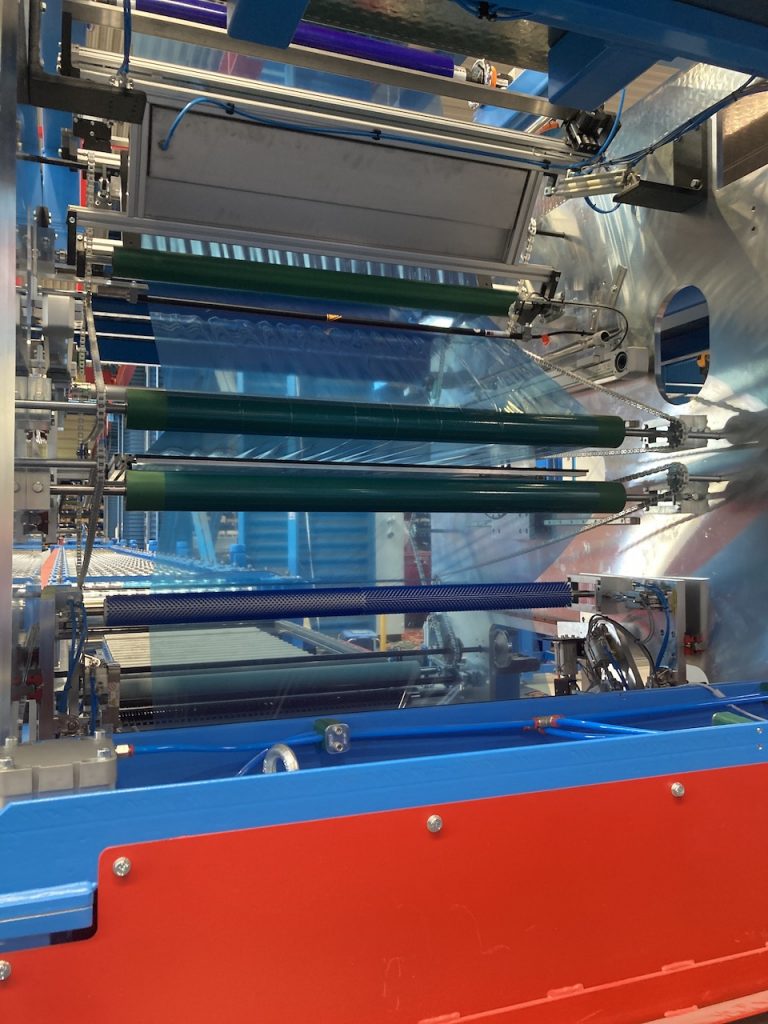

- The protective film had to be able to run at a maximum throughput speed of 10 m/sec in 3-shift operation. This means that the film had to be changed without stopping the machine.

- Bubbles and folds under or in the film cause imprints during further processing – e.g. profiling – that do not allow our current understanding of quality – this had to be solved with stretch rollers and controlled film tension during the entire process.

- The real challenge, however, lay in the application itself, which Refoil solved to the operator’s satisfaction using a familiar but adapted technique